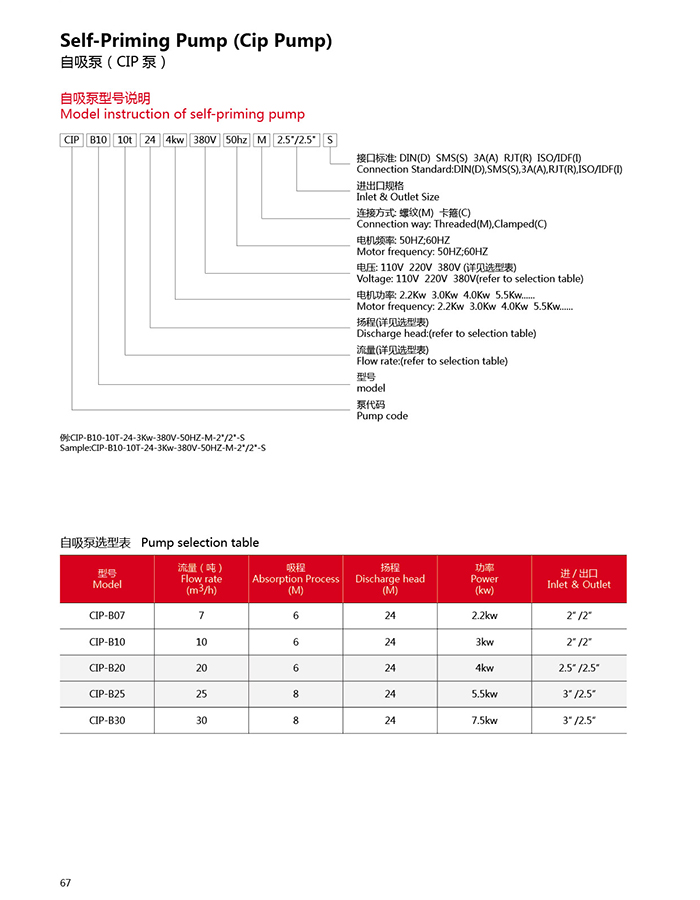

Self-Priming Pump (Cip Pump)

Applications

The pump is a sanitary side channel self priming pump, it' s suitable for food

processing, pharmacy and chemical industry.

It is specially designed for pumping materials containing air or gas, and it can also

be used for negative suction with prior priming as well as with filtration equipment.

It can be used with wine, oil, syrups, volatile products such as alcohol, acetone and

other solvents,or with products at temperatures close to boiling point. However, the

main use of this pump is for CIP return.

Options

·Mechanical seal in SiC/SiC

·Gaskets in FPM(Viton) and PTFE

·Inlet&outlet connections: Clamp,Thread, Flange,DIN, SMS,3A,RJT

Technical specifications

·Max.flow:30m3/h/132 GPM

·Max.head:40 H(M)

·Max.pressure:3Bar/ 43 PSI

·Max.operating temp.:120℃/ 248°F

·Max. rev.:17S0 min

·Max.suction height:8m/22 ft

Operating principles

The impeller is housed between the inlet body and the venturi casing and it rotates

in conjunction with the pump shaft.

The rotation of the impeller and arrangement of the side channel, creates a negative

pressure inside the inlet body, which generates the suction force of the pump. At the

same time, the fluid receives energy in the form of kinetic energy and pressure

energy, and this impels it through the impeller casing.

Materials

·Parts in contact with pumped media:AISI一316/304

·Other parts:AISI-304

·Gaskets (standard):EPDM (FDA)

·Mechanical seal (standard):C/SiC/EPDM

·Internal surface finish:Polished

·External surface finish:Sandblast

Design and features

·Casing manufactured with cold-formed plate.

·Stainless steel investment casting inlet body and impeller.

·Mechanical seal prevents contacting between the springs and the pumped fluid

·Stainless steel support